Descripción

MR ATC Line

Auto Tool Changer

The CNC Routers MR ATC Line have the capacity to equip 6 or 12 different tools at once depending of the model and are able to change the tools in-use automatically without having to stop the cutting, engraving or milling process.

This CNC machines comes with a flat bed measuring 4′ x 8′, 5’ x 10’ and 6.5′ x 10′.

The MR ATC Line offers two processing modes, high precision mode, which focuses mostly on the quality of your work and high speed mode, which focuses on getting the job done as fast and efficiently as possible.

Another useful characteristic is the machine’s ability to recover from power outages and resume interrupted work quickly and accurately.

Fast and safe

On top of being fast, easy and efficient, the MR ATC Line is also safe.

The machine analyzes each file carefully and alarms you if there’s anything wrong with the file uploaded or itself at the time of production.

The CNC Routers MR ATC Line comes with an 8-inch LED monitor,

ARM 11 core processing CPU with 128 RAM for stronger data processing capability.

The MR ATC Line comes with 1-year warranty by manufacture and free phone support by BuchiCNC LLC.

- ArtCAM individual software for design and cut.

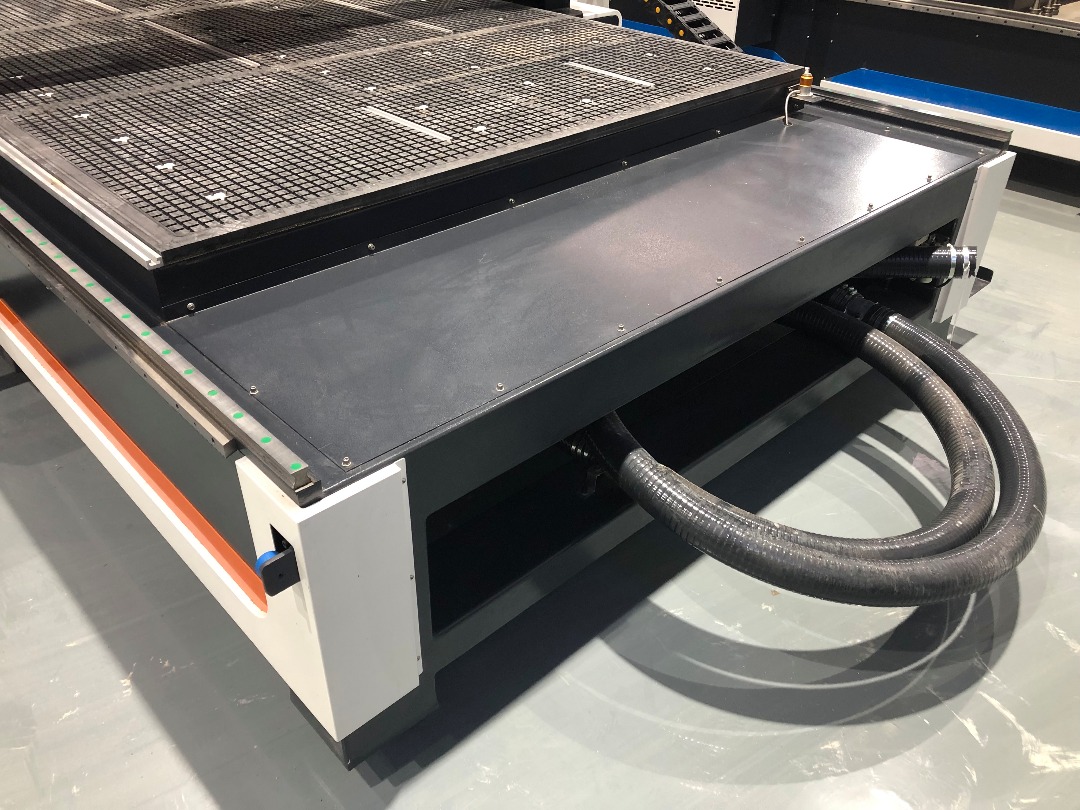

- NEW! Vacuum table designed for the machining of materials with high precision accuracy.

- NEW! NK260 CNC router Control with hand wheel control system.

- ARM 11 core processing CPU with 128 RAM. Stronger data processing capability

- 8 gears of spindle speed.

- 8 inches LED Monitor, Resolution of 800*600. Easy to learn and use, simple and quick.

- Tool management: Linear tool magazine, auto measurement and manual measurement.

- Types: fixed calibration, mobile calibration, first calibration and calibration after tool change.

- Full offline operation, larger storage space: work with SD card and U-disk, 256MB internal storage which can store much more machining files.

- Intelligent memory: power failure recovery and breakpoint resume, knife break continue engraving, not only saves the position, but also memories the file name, ensure continue processing from break point quickly and accurately.

- Portable mobile storage mode: hand-held controller has U-flash disk mode to be used like a flash disk by connecting to PC.

- The cnc router has two processing modes: high precision mode ensures the machining precision and high speed mode ensures the process efficiency, saving processing time.

- Intelligent machining file read-ahead: system checks the file before machining in the cnc router and user can change this setting, same file only pre-read for one time and can be skipped as needed.

- Security and alarm: alarms of program error, operation error, over travel error, alarms of spindle and driver.

- Perfect encryption functions: encryption of hardware, parameters, internal important processing files, prevention of modification, delete, copying, ensures the customers technical information and assets safe.

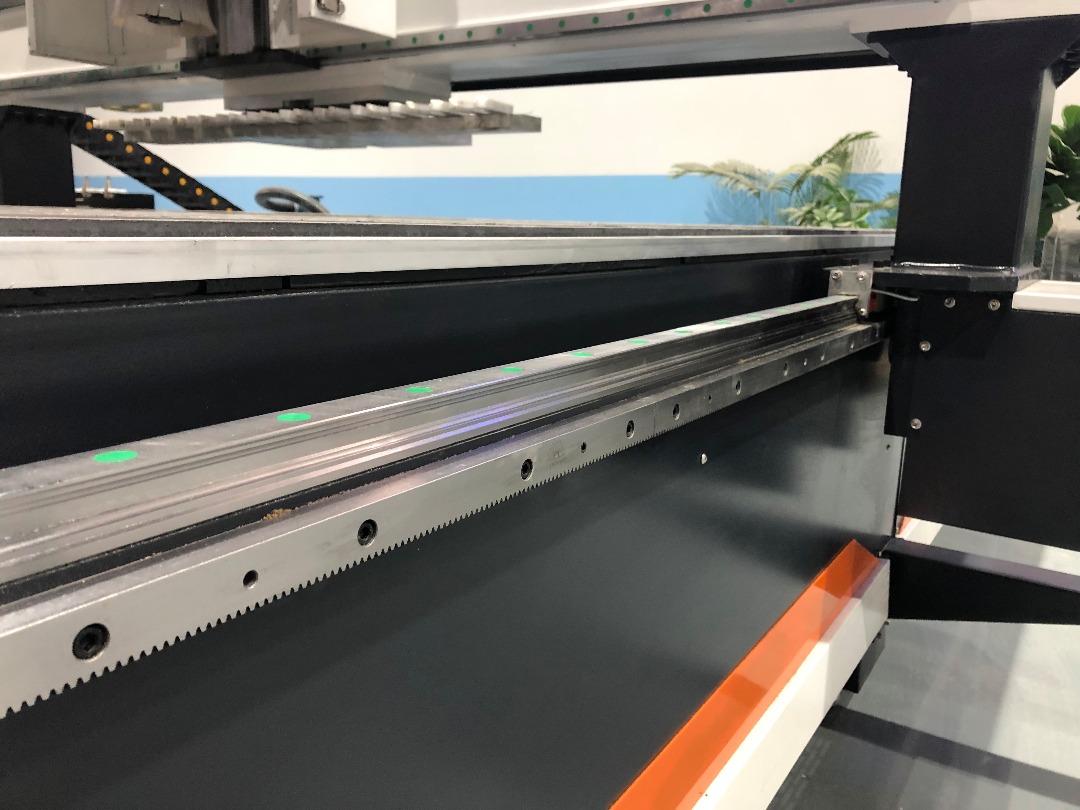

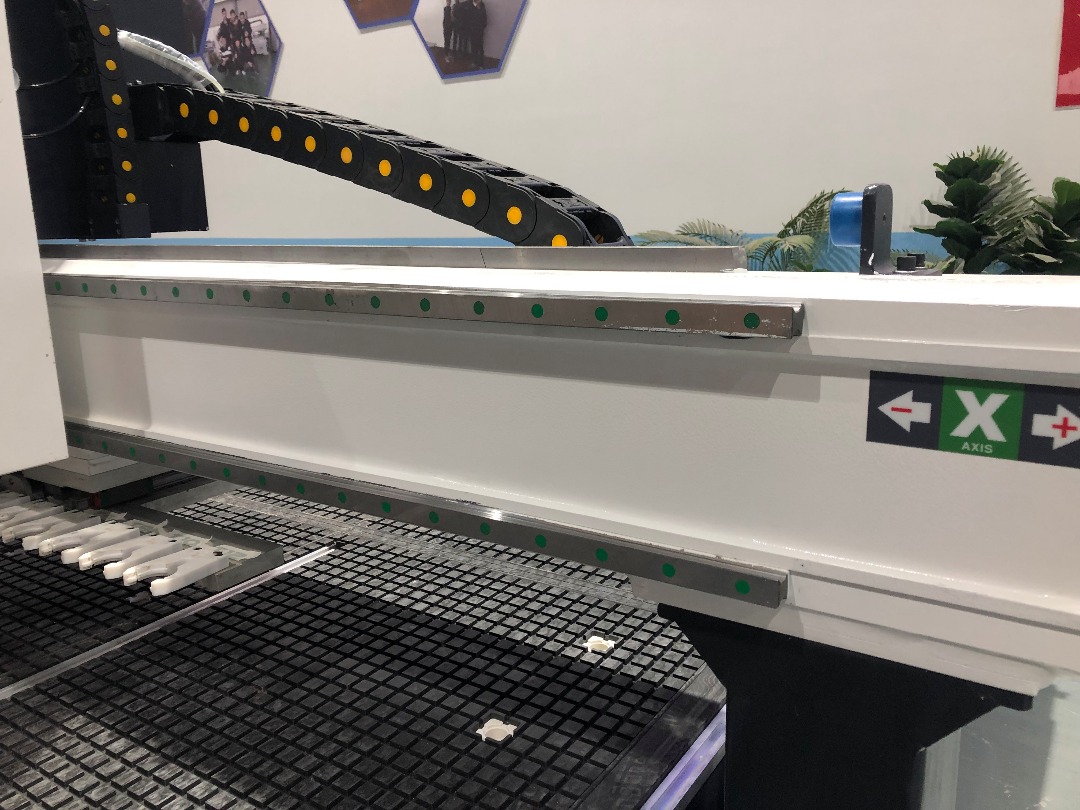

- High quality linear guides that ensure silent, smooth and precise movement.

CNC Router tech info

| Control System | NK105 G3 DSP Control system. |

| Spindle | Standard Quality Air Cooled with 6 tools linear ATC. Optional Italy HSD 9KW Air cooled spindle & up to 12 tools. |

| Machine Body and Gantry | Heavy duty metal welding, quenching and sandblasting. Twice painting. |

| Working Table | TSlot & Vacuum table 5.5 kw air cooling vacuum pump. Optional Becker KVT 3.140 129 m³ vacuum pump. |

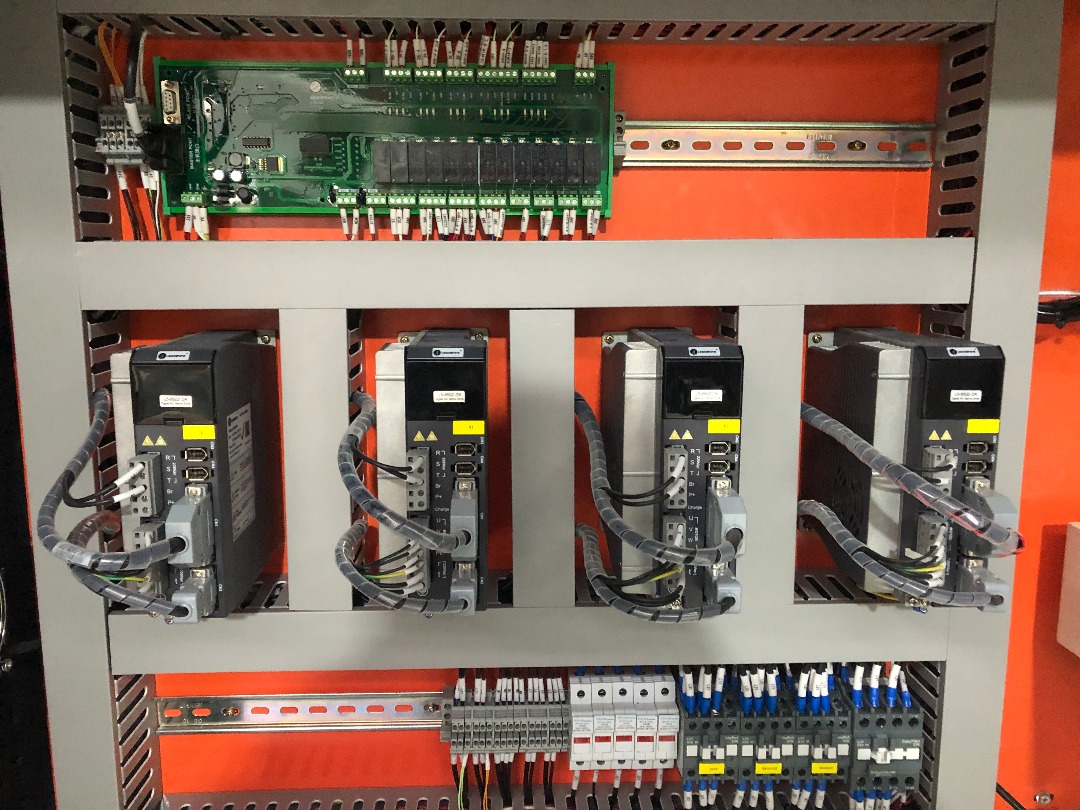

| Driving system | 850 W Servo Motor and Driver. |

| X, Y Axis Structure | 1.25M helical rack and Japan SHIMPO Reducer. |

| Z Strucutre | Ball screw. |

| X Y Z Axis Square Rails | 30 Square rails for Y,25 for X and Z |

| Inverter | 11 Kw Inverter. |

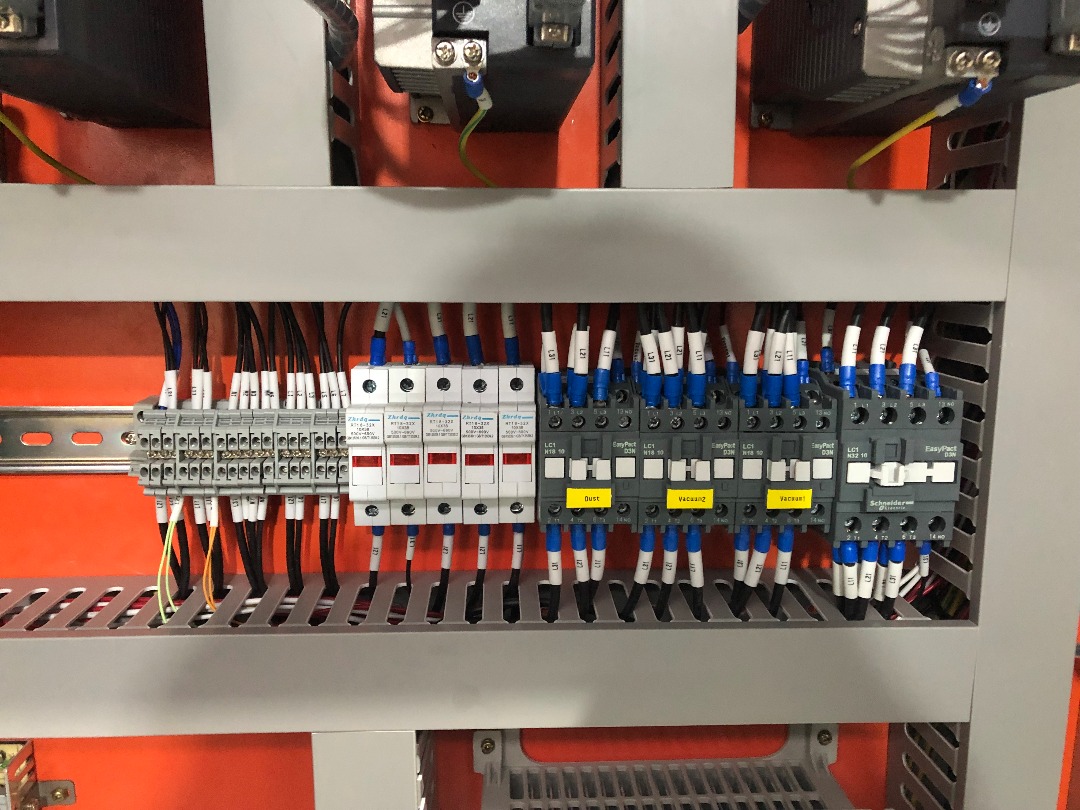

| Electric Parts | France Schneider. |

| Limited Switch | Japan Omron. |

| Machine cable | German Siemens OEM factory cable. |

| Oil Lubrication | Hand control with Aluminum oil pipe. |

| Machine working size | X Axis 51.18 in, Y Axis 98.42 in, Z Axis 7.87 in. |

| Machine Size | 4′ x 8′ – 5′ x 10′ – 6.5′ x 10′. |

| Machine Max Travel Speed | 16.40 ft/min. |

| Machine Max Working Speed | 6.56 ft/min. |

| Machine Voltage | 220 V, 60 Hz. |

| Machine software | Artcam. |

| Assist Loading Roller | Yes. |

| Control Switch | German Moeller. |

| Dust Prevention System | Woolen Blanket Square Rails Clean. |

| Machine Head Board | Aviation Aluminum Alloy Thickening. |

| Other Optional | Dust collector. Mist Cooling Pump. Reducer. Italy HSD Spindle. German Becker Pump. |