Description

WIFI Wireless Control

For speedy service, we add WIFI function for our technician to operate troubleshooting and adjust parameters remotely. Check laser source parameters to analyze failure causes. Check cutting parameters to analyze and adjust new parameters.

Switzerland RAYTOOLS Laser Head

Rotary Knob type focus point adjustment for fine and flexible adjustment. Adjustable range: 20mm, accuracy: 0.05mm. Drawer type mirror seat to make protect glass replacing faster and easier. Both collimating lens and focal lens could apply compound lens for optimal optical quality and cutting result. Modular design with optional collision-proof protective devices or pneumatic knife to realized swiftly switch between welding and cutting. Optional magnetic collision-proof protective modular that would activate reliable separation and immediately light off in case of collision.

- Optimized optical configuration and smooth and efficient airflow design.

- Fully upgraded dust-proof design, double-layer protection, the risk of contamination of the lens is almost zero.

- laser head with anti-collision function.

- focus adjustment and manual correction, fine and flexible adjustment, adjustable range 20 mm, precision 0.05 mm.

- The collimating mirror, focusing mirror and nozzle have a cooling structure.

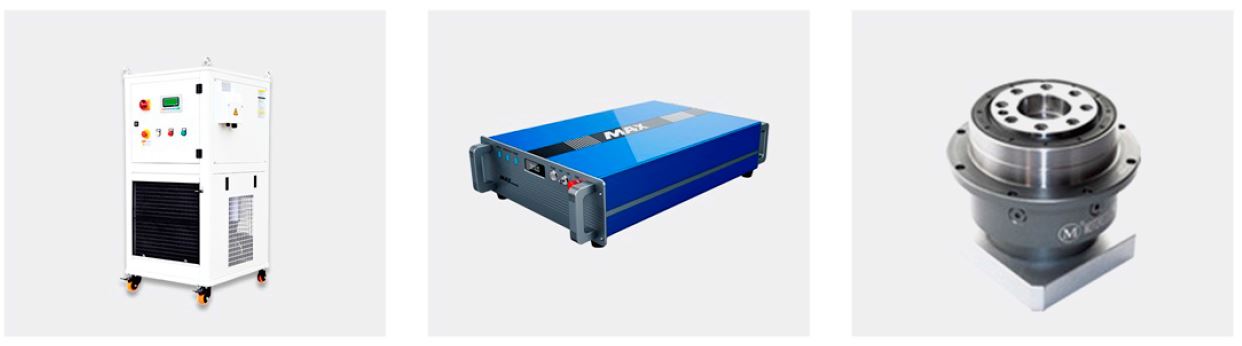

France MOTOREDUCER

Satellite gears are double-supported on hardened and ground shafts with full-complement needle bearings increasing torsional stiffness. Backlash ≤ 3 arcmin. Standard operating temperature range is -15℃ to 45℃. Protection rated IP 65 standard.

Japan Yaskawa Servo Motor

These servo motors are built with a compact footprint, yet provide a higher torque while maintaining an inertia well within the medium range.

- Accuracy

Realizes closed-loop control of position, speed and torque; overcomes the problem of stepping motor out of step.

- Rotating speed

High speed performance, general rated speed can reach 2000~3000 rpm.

- Adaptability

High strong anti-overload capability, load three times the rated torque, suitable for occations with transient load fluctuations that require fast start.

- Stable

Smooth operation at low speed, no stepping similar to stepper motor when running at low speed.

- Timeliness

Motor acceleration and deceleration on short time, generally within tens of miliseconds.

- Comfort

Significantly reduced heat and noise.

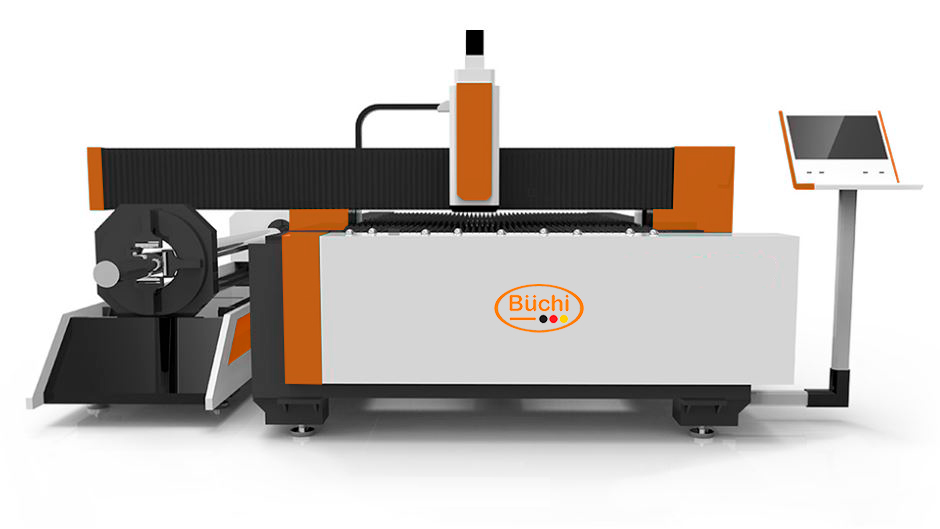

Technical Parameters

| Model | XTF 1530 | Option | |

| Working Area | 59*118 in | According to demand | |

| Laser Power | 500w/800w/1000w/1500w/2000w/2500w/3000w | ||

| Max Moving Speed | 393 in/min | ||

| Max Cutting Speed | 1378 in/min | ||

| Positioning Accuracy | 0.001 in | ||

| Reposition Accuracy | 0.0008 | ||

| Min Line Width | 0.004 in | ||

France Schneider Electronic Component

Circuit protection against short-circuit currents, Circuit protection against overload currents, Breaking and industrial disconnection as per standards IEC/EN 60947-2. Overvoltage resistance, High performance limitation, To fast closing independent of the speed of actuation of the toggle.

Japan NSK Bearings

These bearing housings have square flange which can be easily attached to a machine with four bolts. With its simple mounting face, this bearing unit is widely used.

Laser Source

Wavelength range:1070~1090nm Beam quality TEM00 (M2<1.8) Forced air/Water cooling More than 100000 hours work-life of pumped diode.

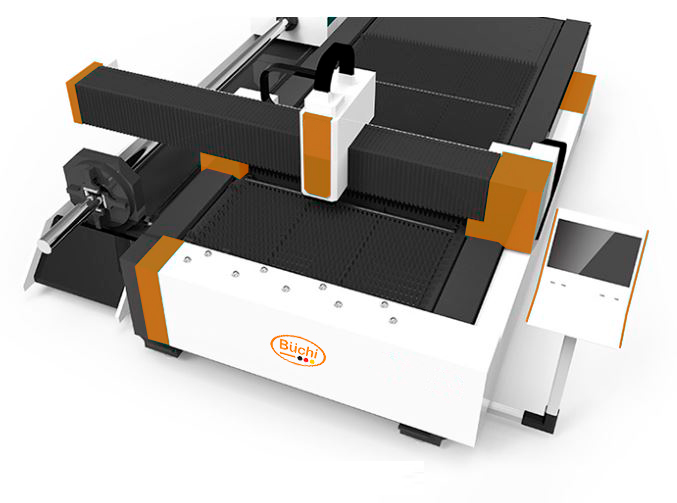

Automatic Lubrication System

Electrical lubrication is a kind of gear pump with rational construction, great performance and comprehensive functions. By connection with program control system in the main machine, the lubrication system could oversee oil level within tank as well as oil transmission pressure and set lubrication periodicity, which will effectively prevent rust within lubrication system to ensure cutting accuracy.

- Protection of the machine

The oil lubrication is applied when is required by the fiber laser cutter to keep in optimal conditions the transmition components. - Profits increased

Extend the service life of the fiber laser cutting machine and reduce the maintenance time of the equipment.

Laser Cutting System

The software is embedded with a rich memory of laser cutting setting references, flexible layout designs and tool path editing, data import/export, bridging, co-edge, beam compensation, curve smoothing, division, combination, automatic identification of exterior and interior modes and so on, compatible with laser source brands such as IPG, SPI, JK, Raycus, etc., capable of running for CO2 and YAG.

Application

Widely used in the processing of advertising board, metal plate structure, Hv/lv electrical ark production, textile machinery parts, kitchen utensils, car, machinery, elevator, electric parts, spring coil slice, subway line spare parts, etc..